Hera Shoes

Comfort mid-sole for high-heeled footwear

Hera designs shoes for those that want all day comfort in a slim and svelte high heel silhouette. I was tasked with the challenge of solving this worldwide problem with massive constraints of thickness and weight. I discovered that the most comfortable shoes had the thickest soles which were unfortunately perceived as unattractive. Thus, I sought out ways to minimize the thickness of the sole without compromising on cushion or rigidity. I replaced the traditional midsole constructed around a metal shank with one made from ultralight, thin carbon fiber & cushion elastomer. This achieved double the cushion within the same thickness as traditional construction.

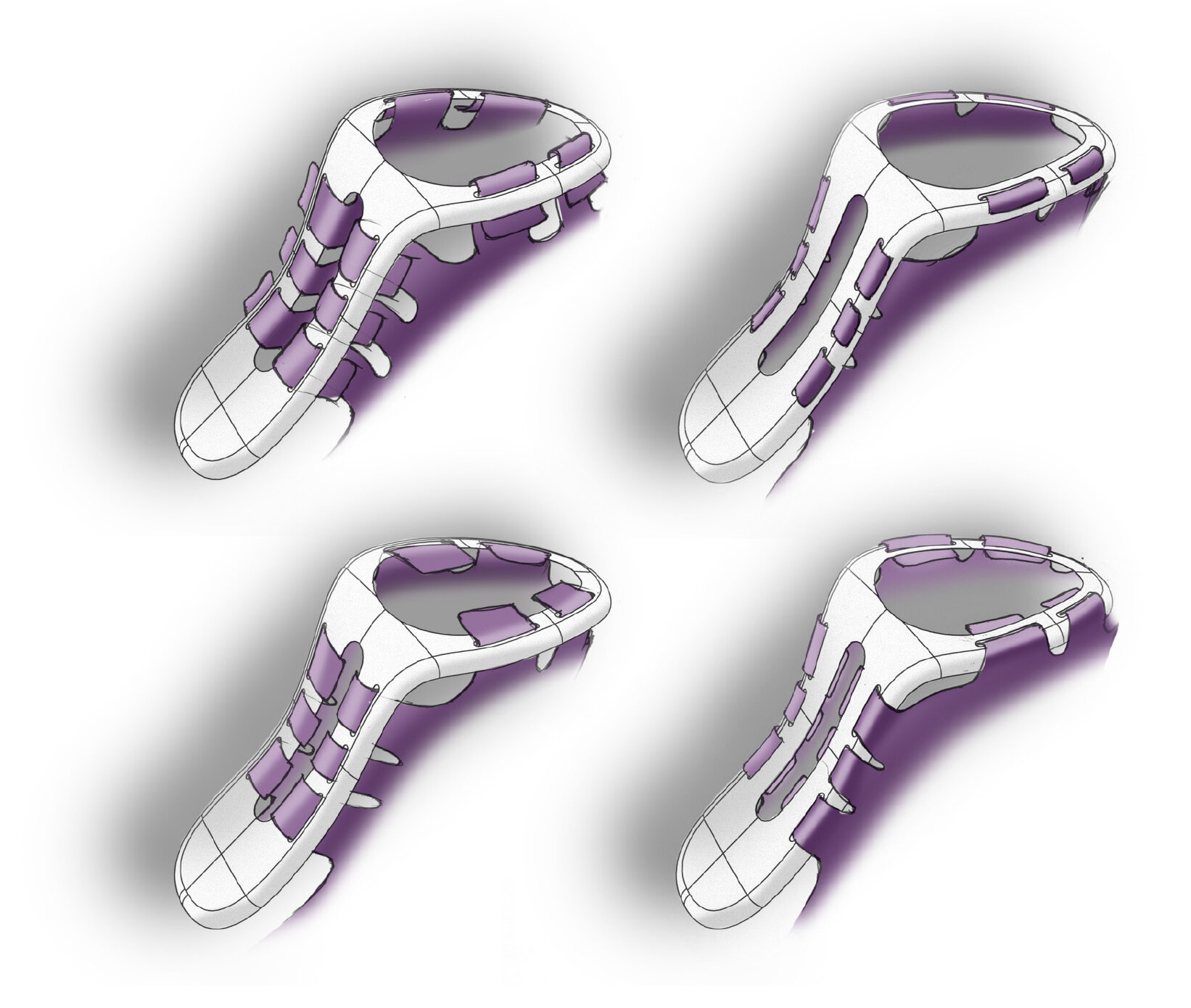

I used a variety of methods to prototype throughout the project. The first step was to build our master surfaces by 3D Scanning a last, modelling the reference surfaces based on this data. After that we 3D printed and adjusted the inner & outer surfaces of the midsole to ensure correct fit with the last.

We went through a few iterations of 3D printing to communicate design intent as well as discussing methods of assembly with our shoemaker partners. This stage allowed us to quickly eliminate any ideas that would create more problems later on during manufacturing.

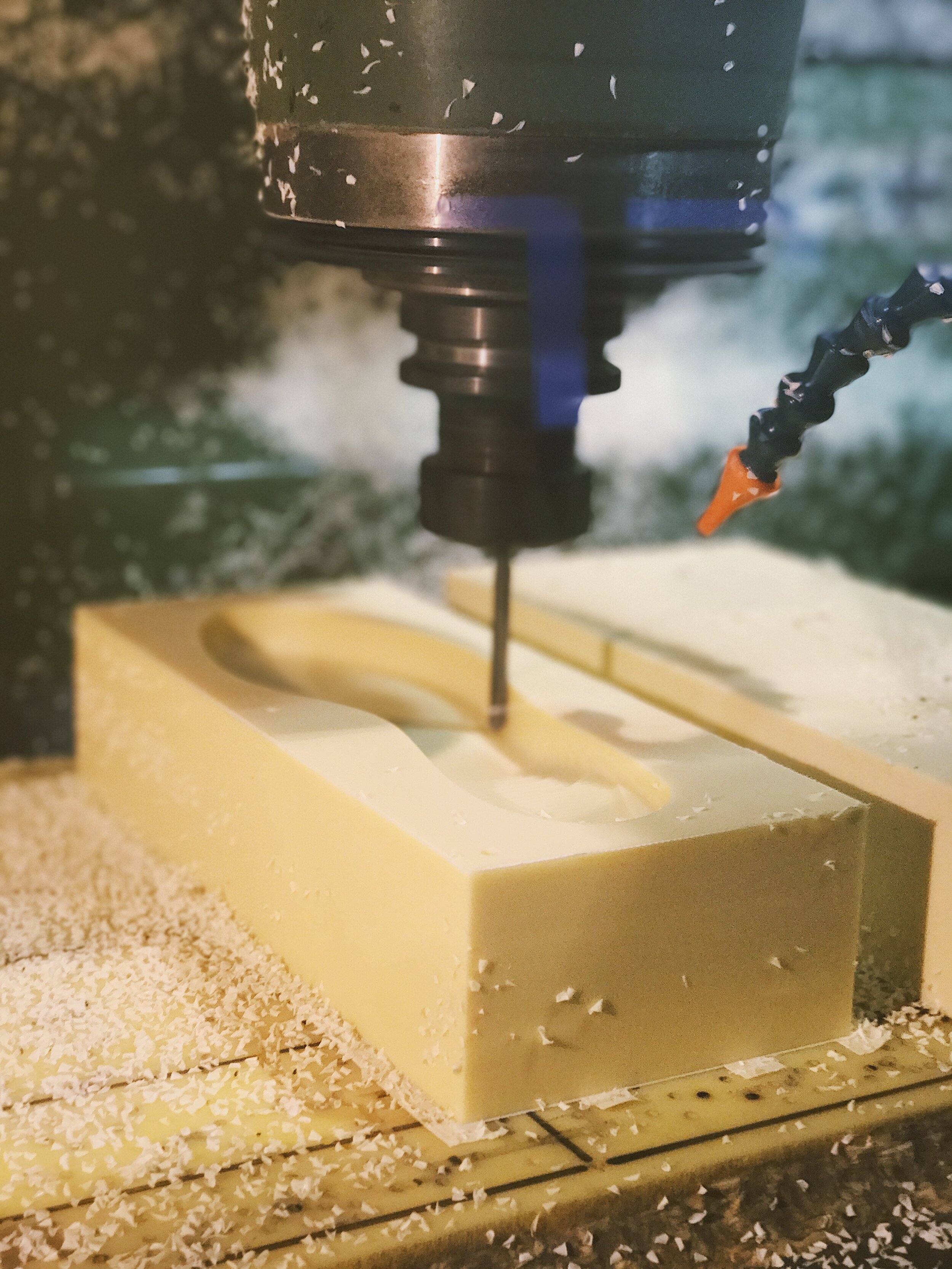

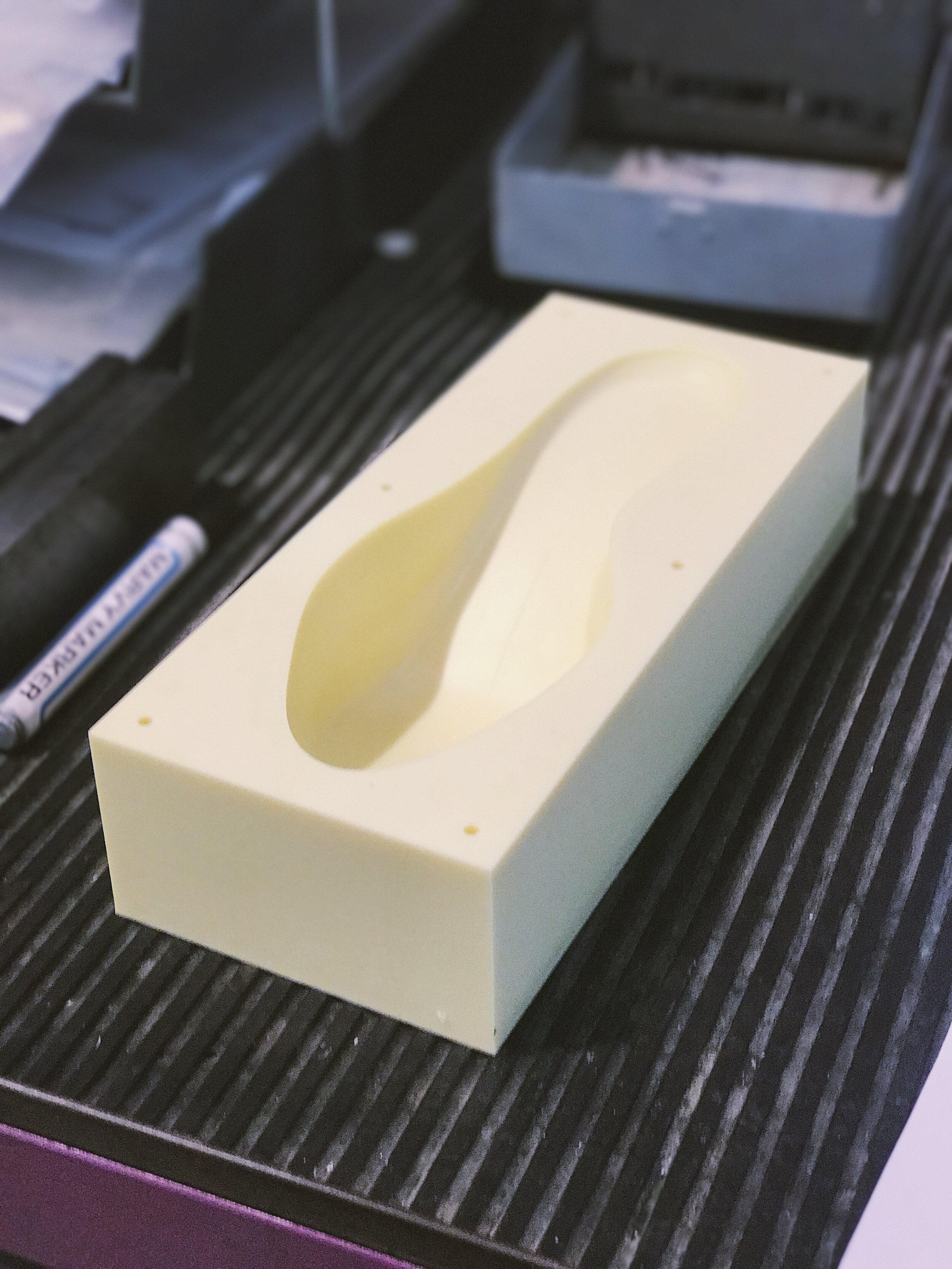

With our 3D data validated and rough assembly process discussed, we created a plastic mold to fabricate the cushion elastomer that would fit on the midsole.

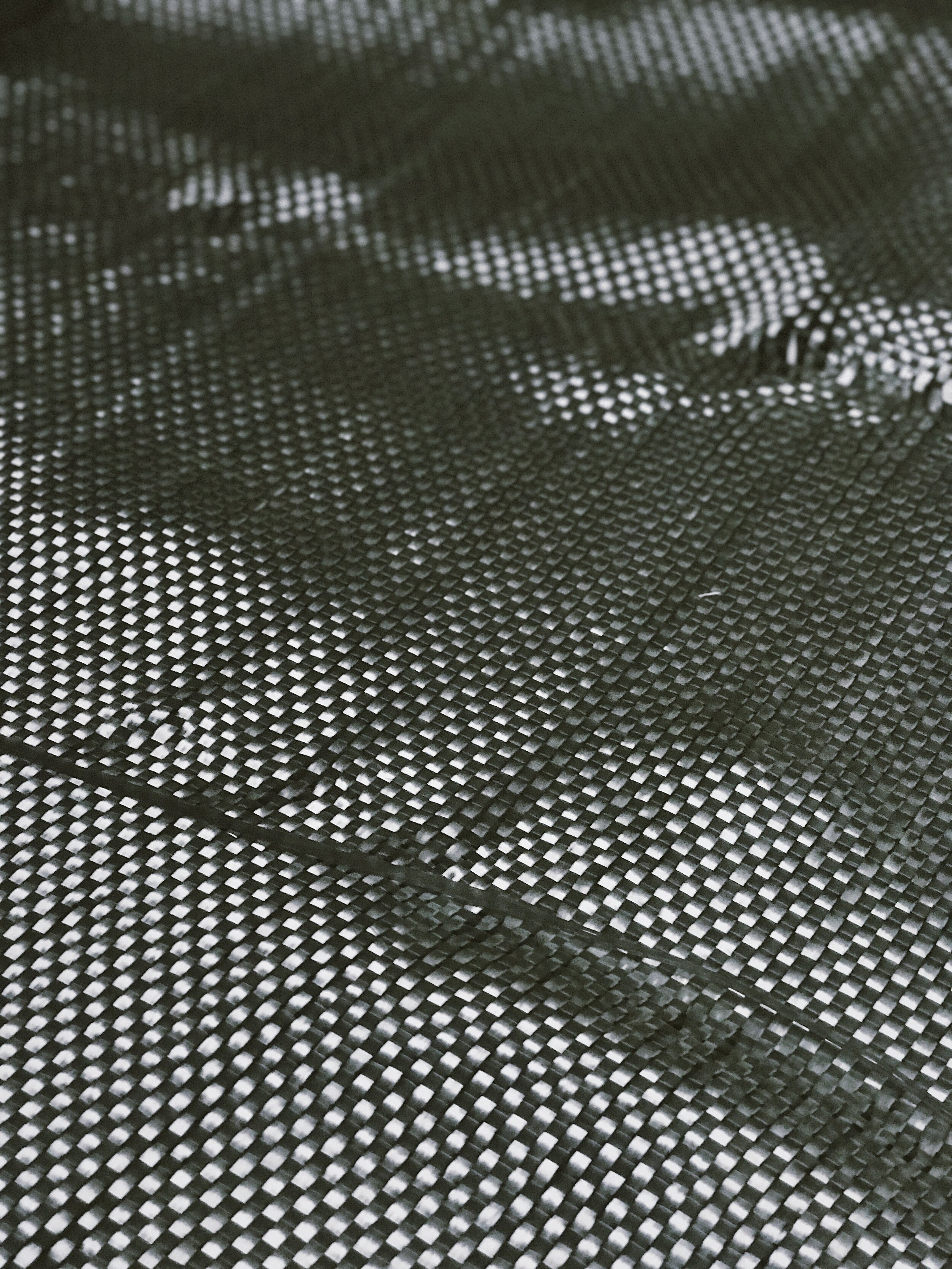

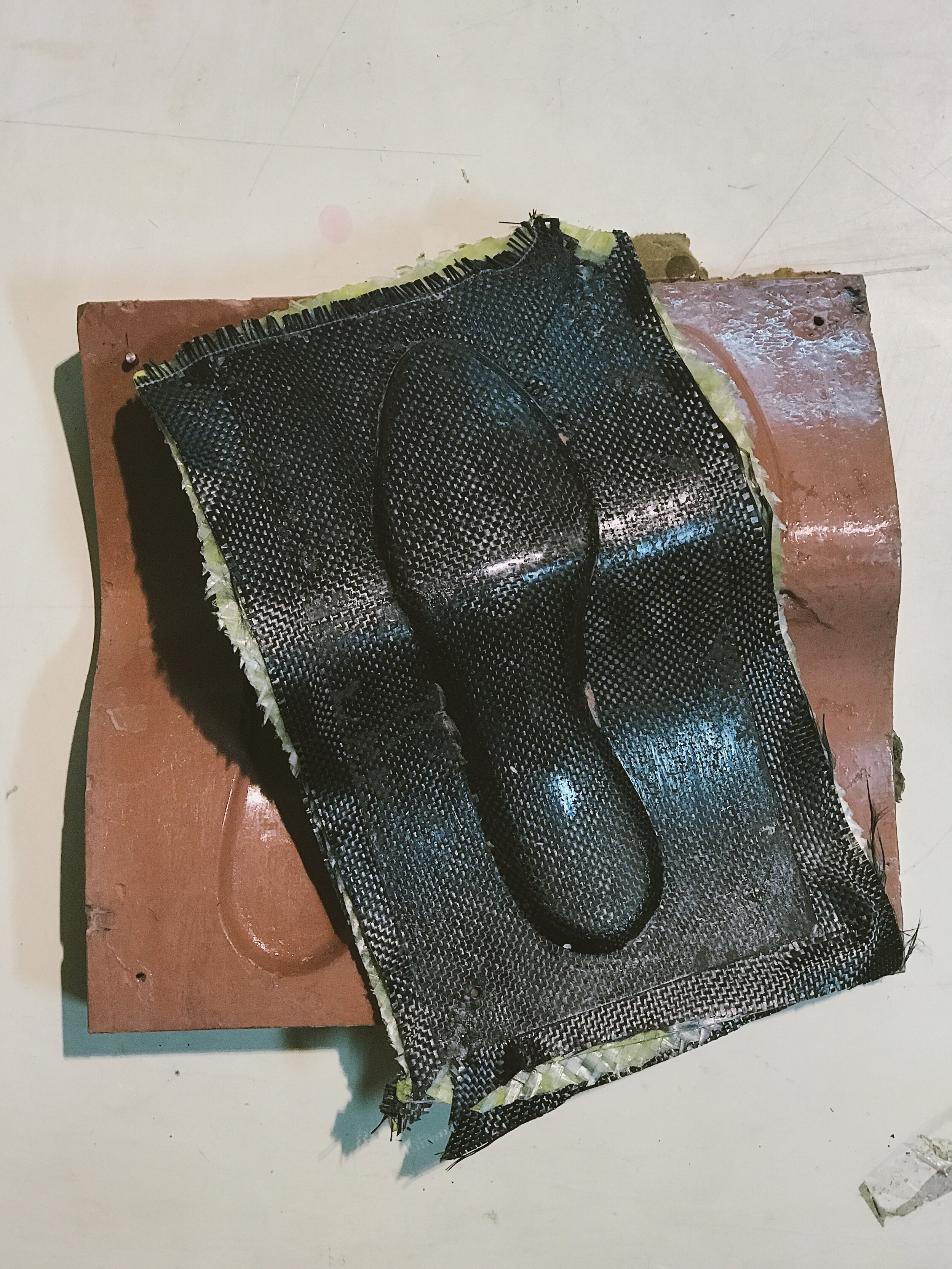

In addition to the plastic mold, we also created a two sided press mold for laying up carbon and glass fibers of varying specifications to construct the midsole.

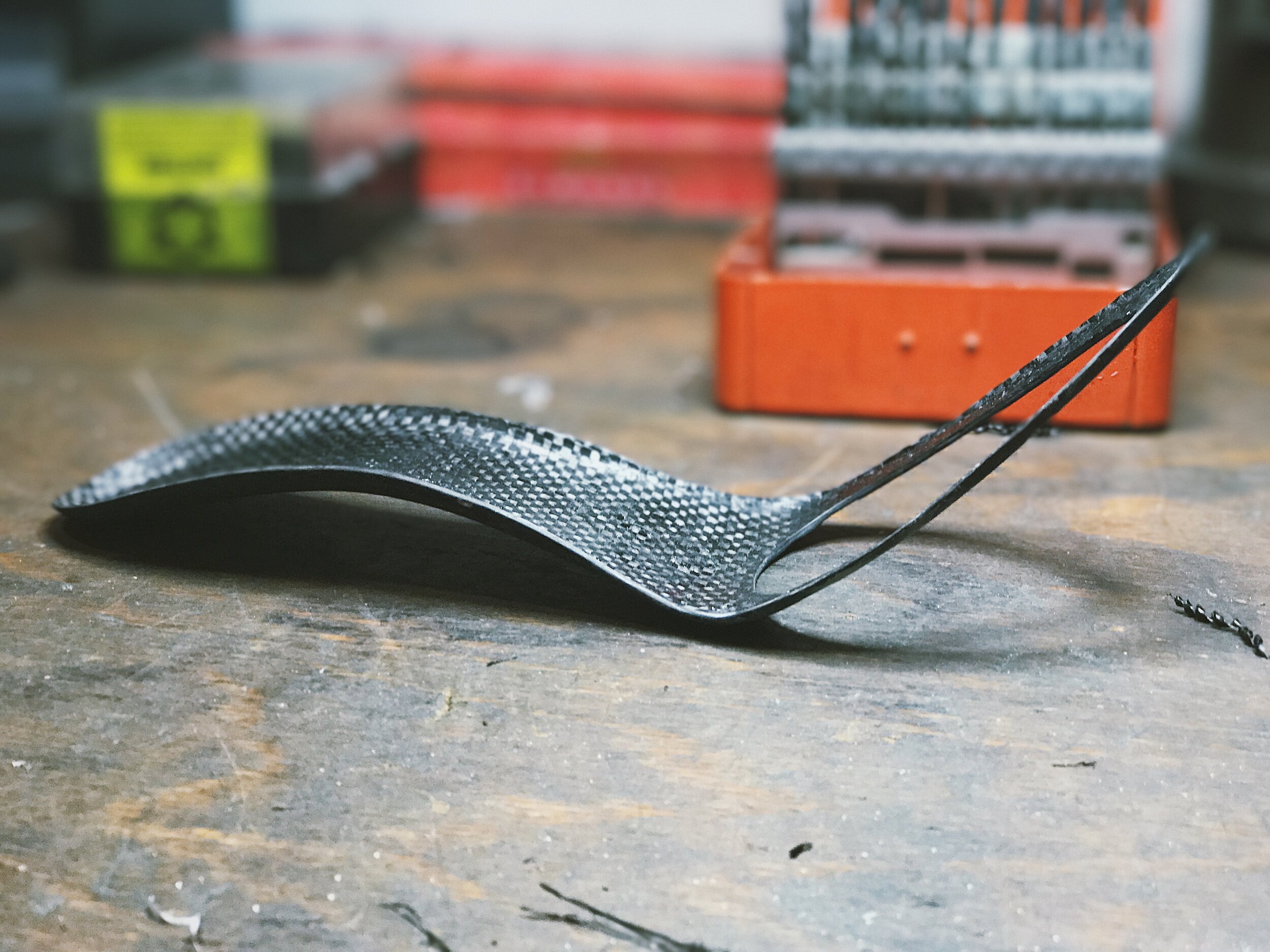

With the two molds fabricated we experimented with various shore hardness and densities of elastomers. The most interesting aspect was the fabrication of glass fiber & carbon fiber midsole. After trying out different thicknesses and layer combinations along with weave directions, we were able to construct an extremely rigid yet flexible midsole. The final layer stack comprised of a sandwich with an inner and outer carbon fiber in opposing weave directions filled in the middle with cheaper glass fibers used as a spacer. This reduced the weight as well as the cost without compromising on strength.

We removed some material in the ball area of the foot which reduced weight and allowed the carbon fiber to flex a bit more without breaking. This was further aided by the elastomer cushion sole working in tandem with the rigid midsole to create a strong yet flexible shoe.