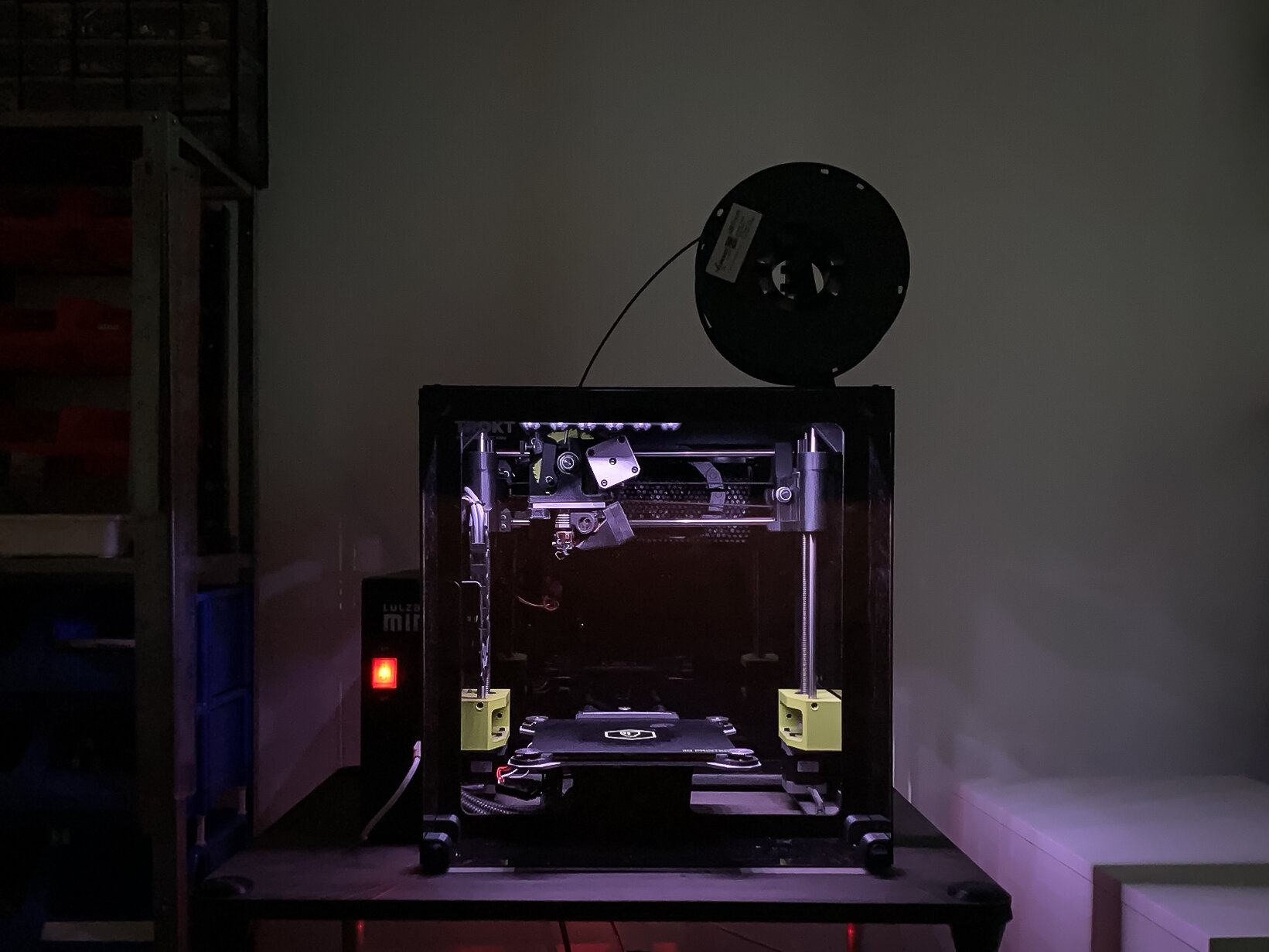

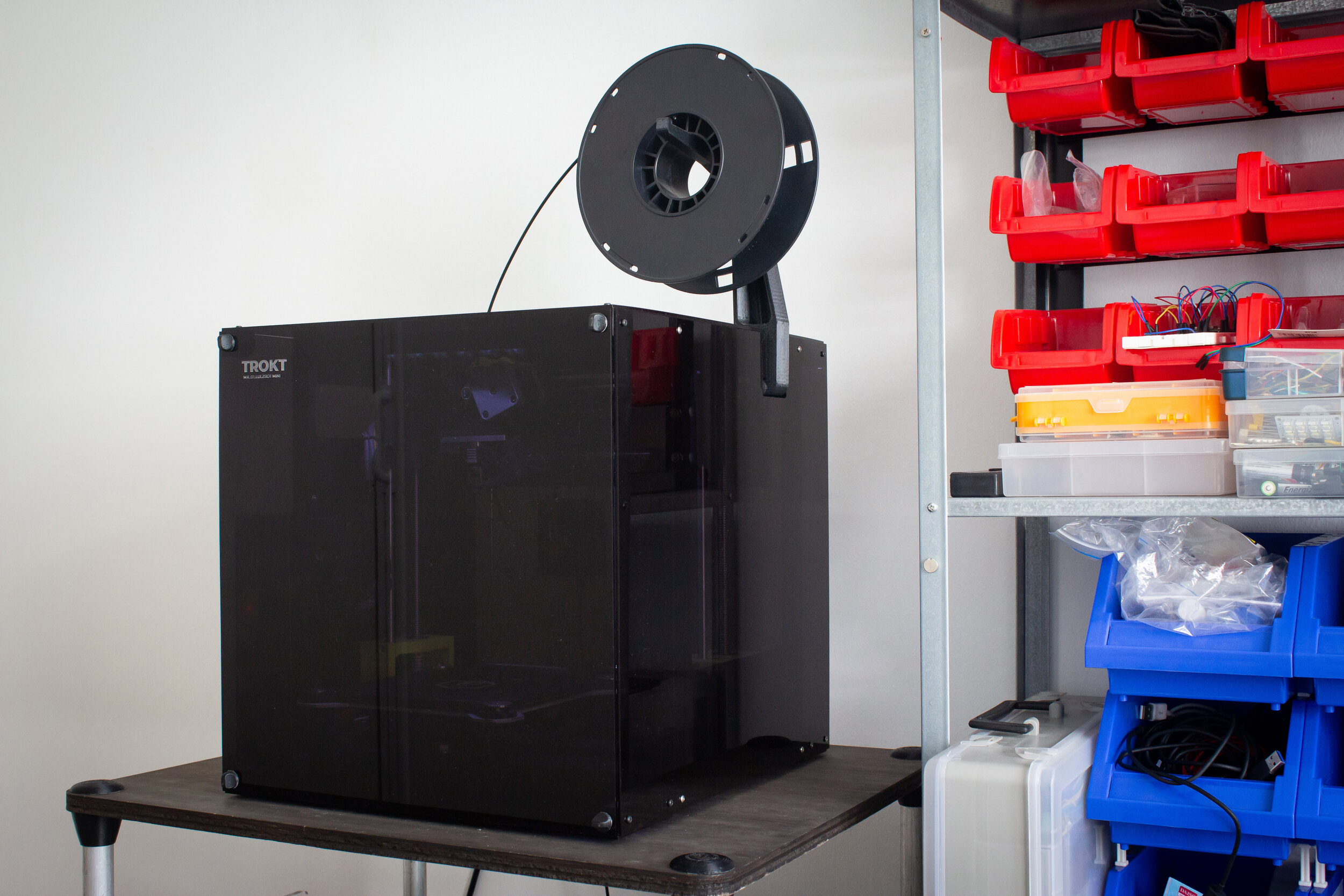

TROKT.MK01.LULZBOT

Air Scrubbing Enclosure for the LulzBot Mini 3D Printer

Building on the TROKT range of evolving Maker equipment and accessories, we sought out to upgrade our existing 3D printer that has served us well for the past five years. The goal was two fold, to provide a protective enclosure and even heating while ensuring that the harmful particles and VOC (Volatile Organic Compounds) found in materials such as ABS are removed from the air surrounding the print. As with all TROKT accessories we sought out simple zero tooling methods to fabricate it. Using lasercut panels, magnets and a few 3D printed fastening blocks, the enclosure is easy to assemble and upgrade.

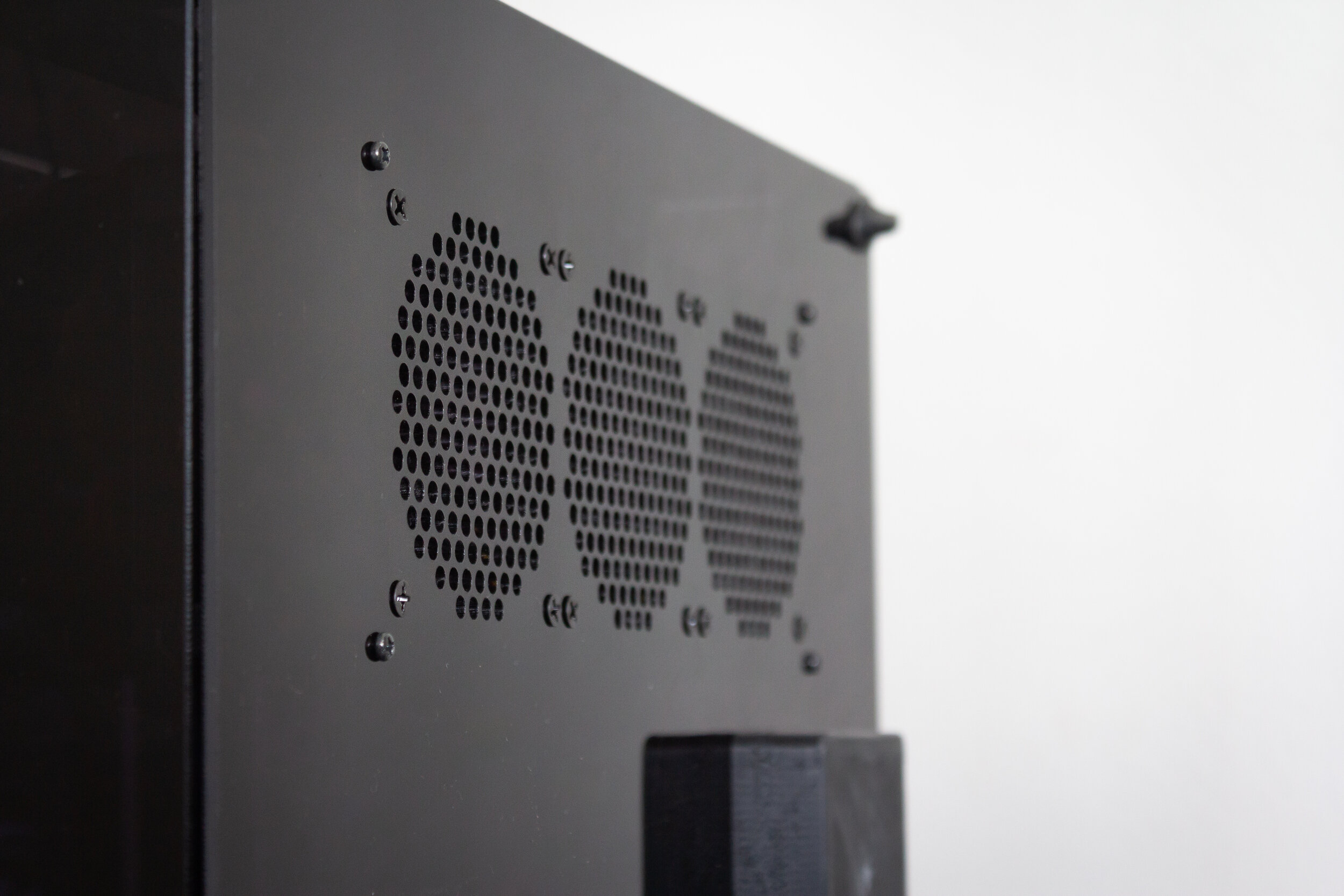

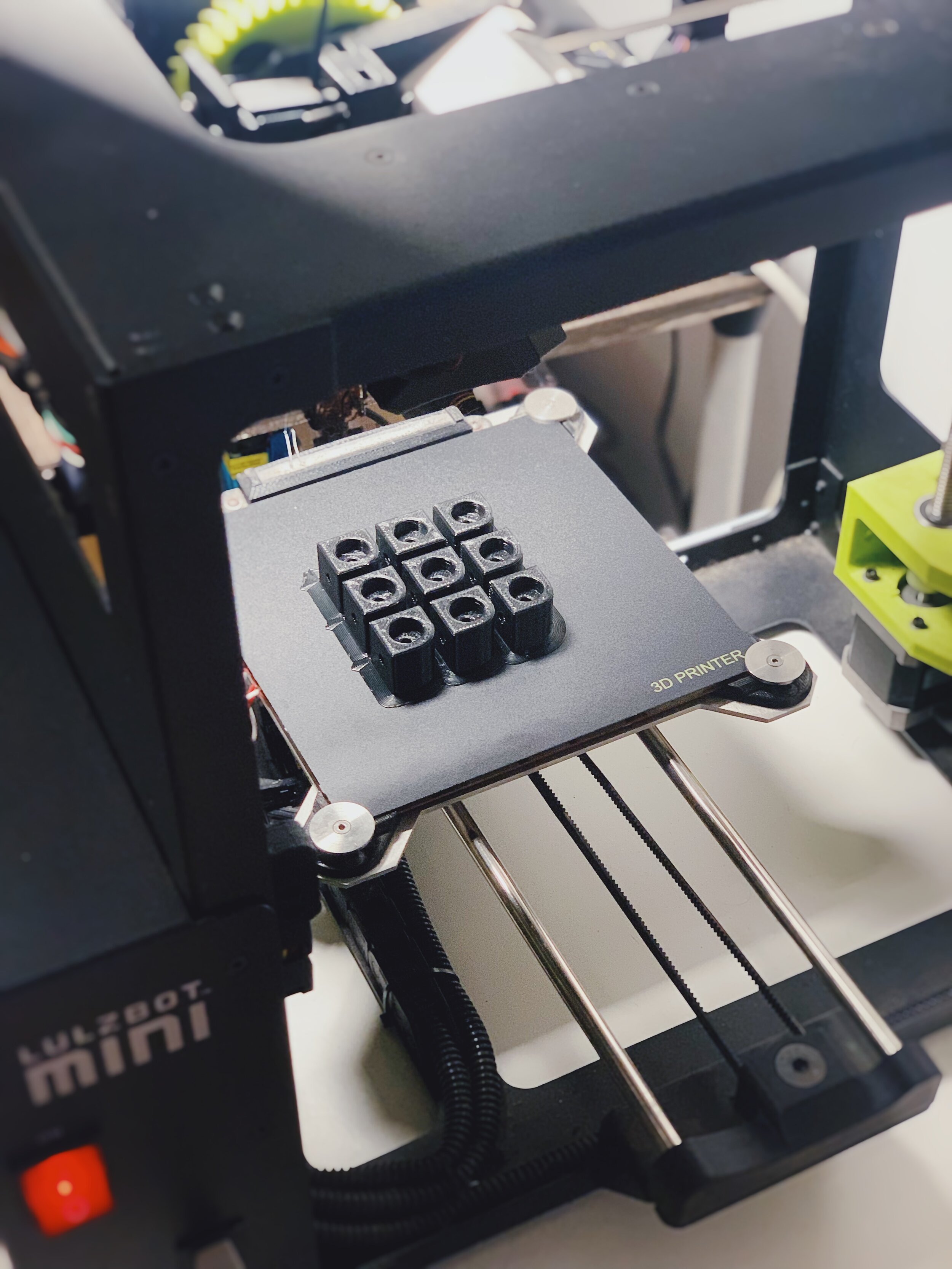

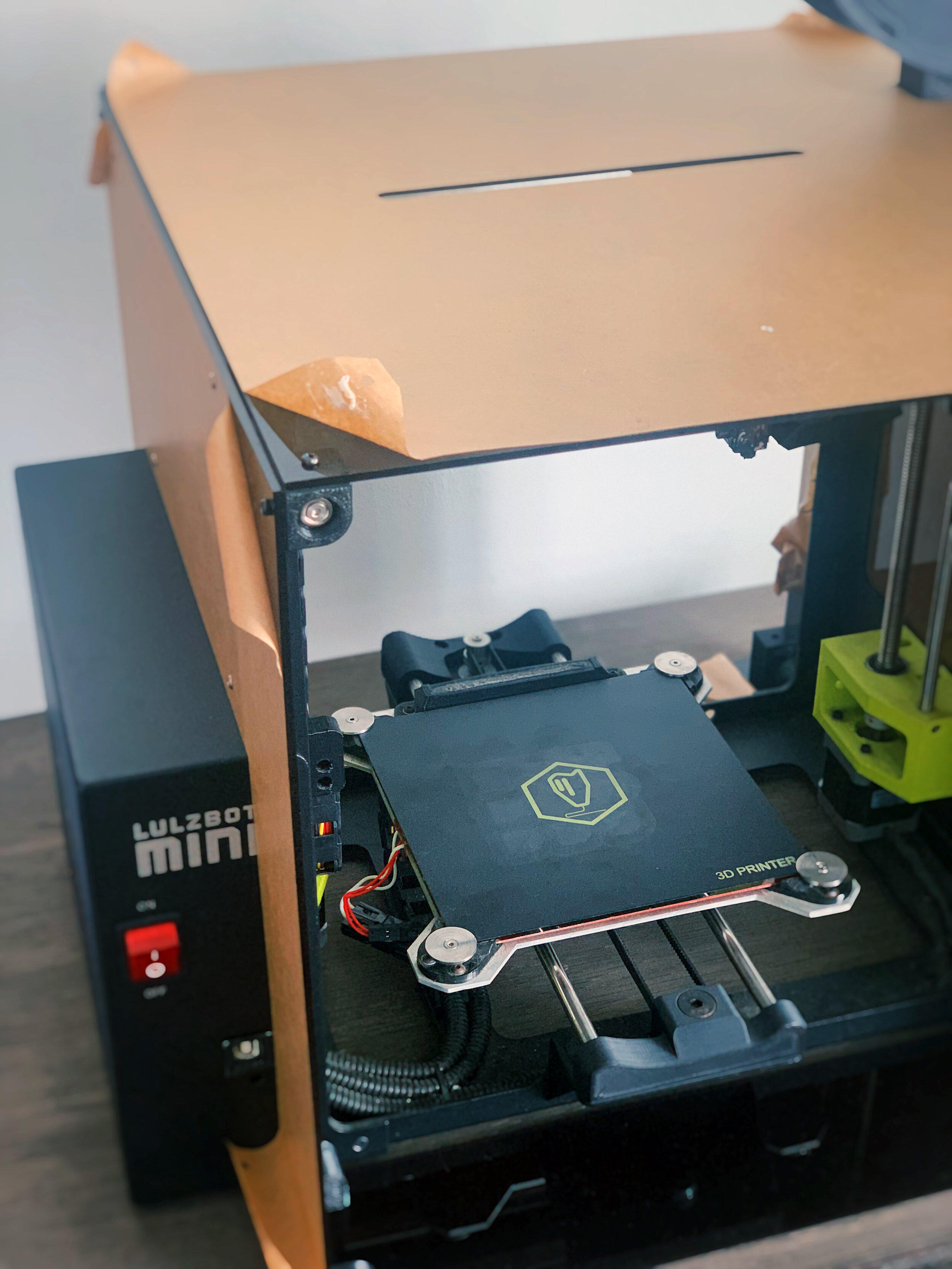

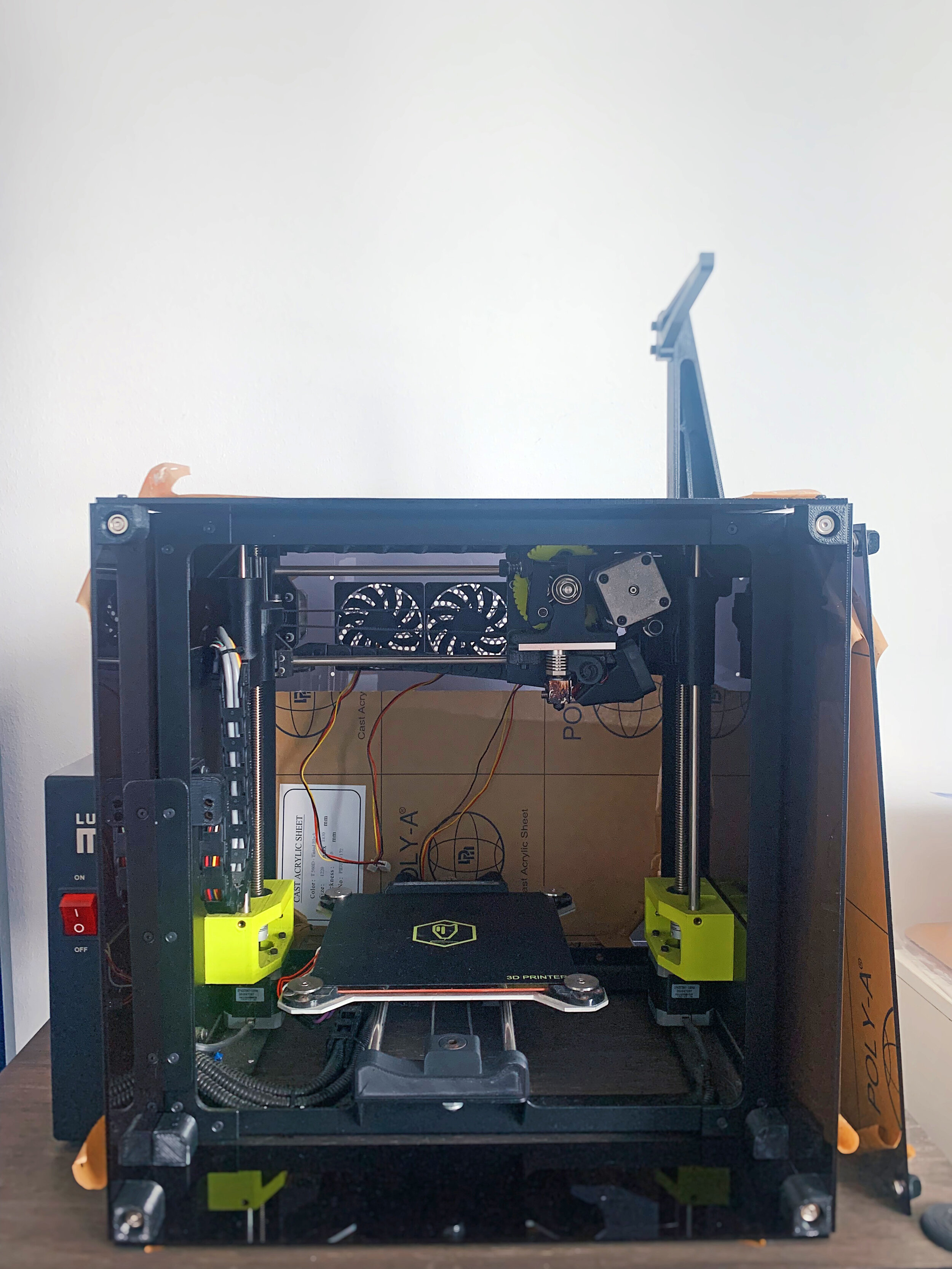

Enclosure Construction

The 3D Printer enclosure is made from 3D printed corner fastening nuts with laser cut acrylic panels for easy assembly. Magnetic hinges were used for the front and back panels as those need to be removed constantly during assembly and use.

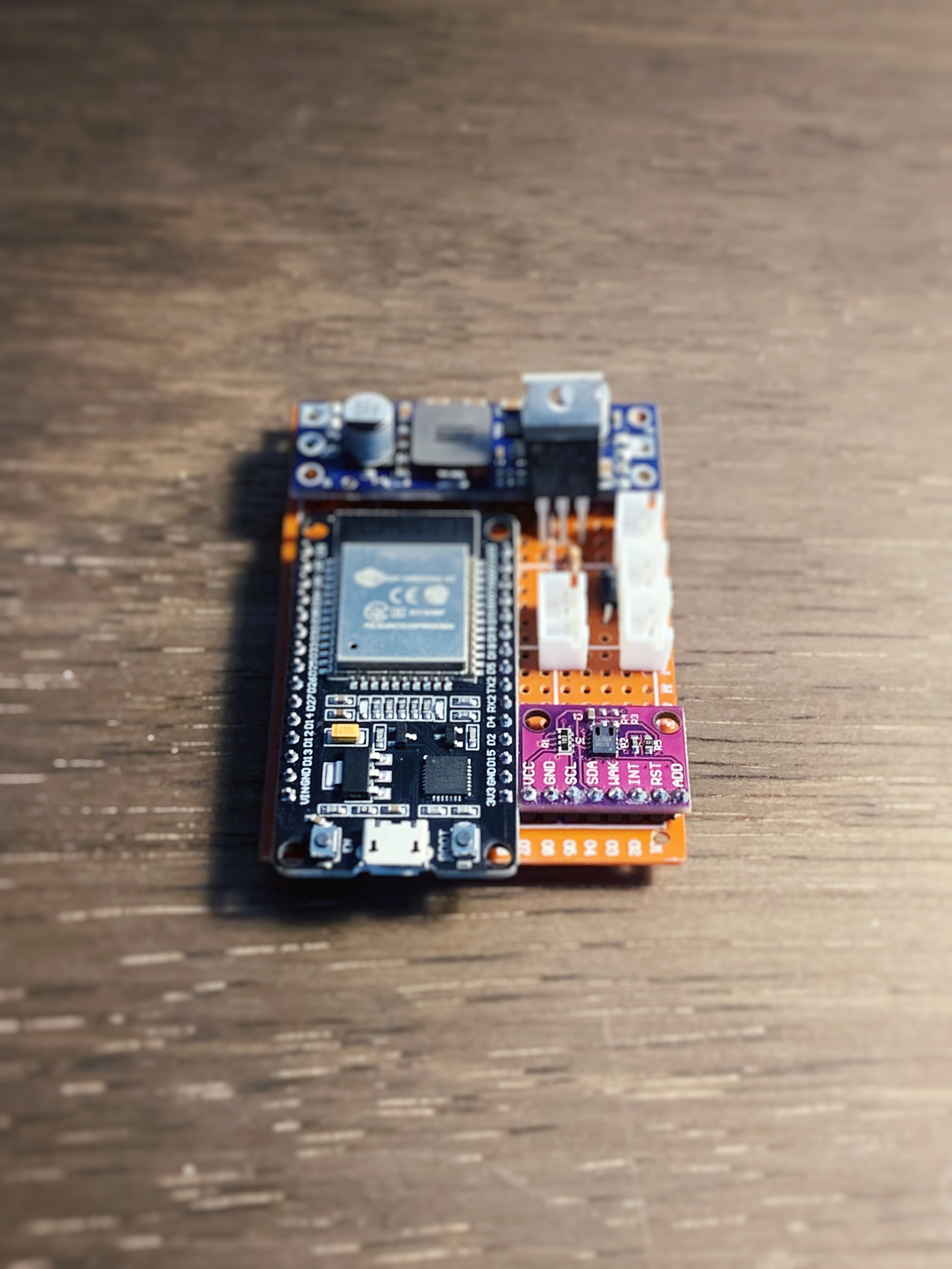

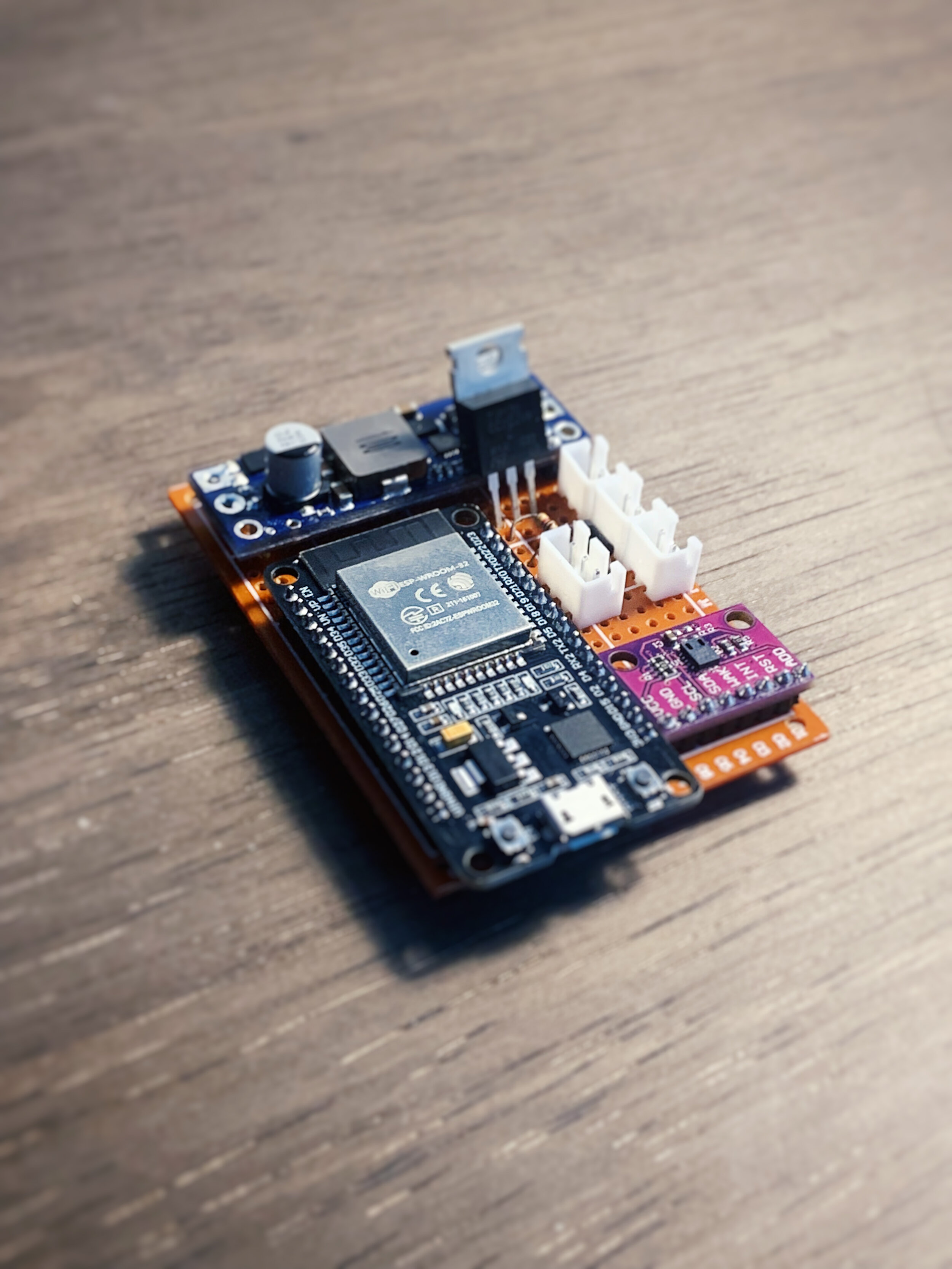

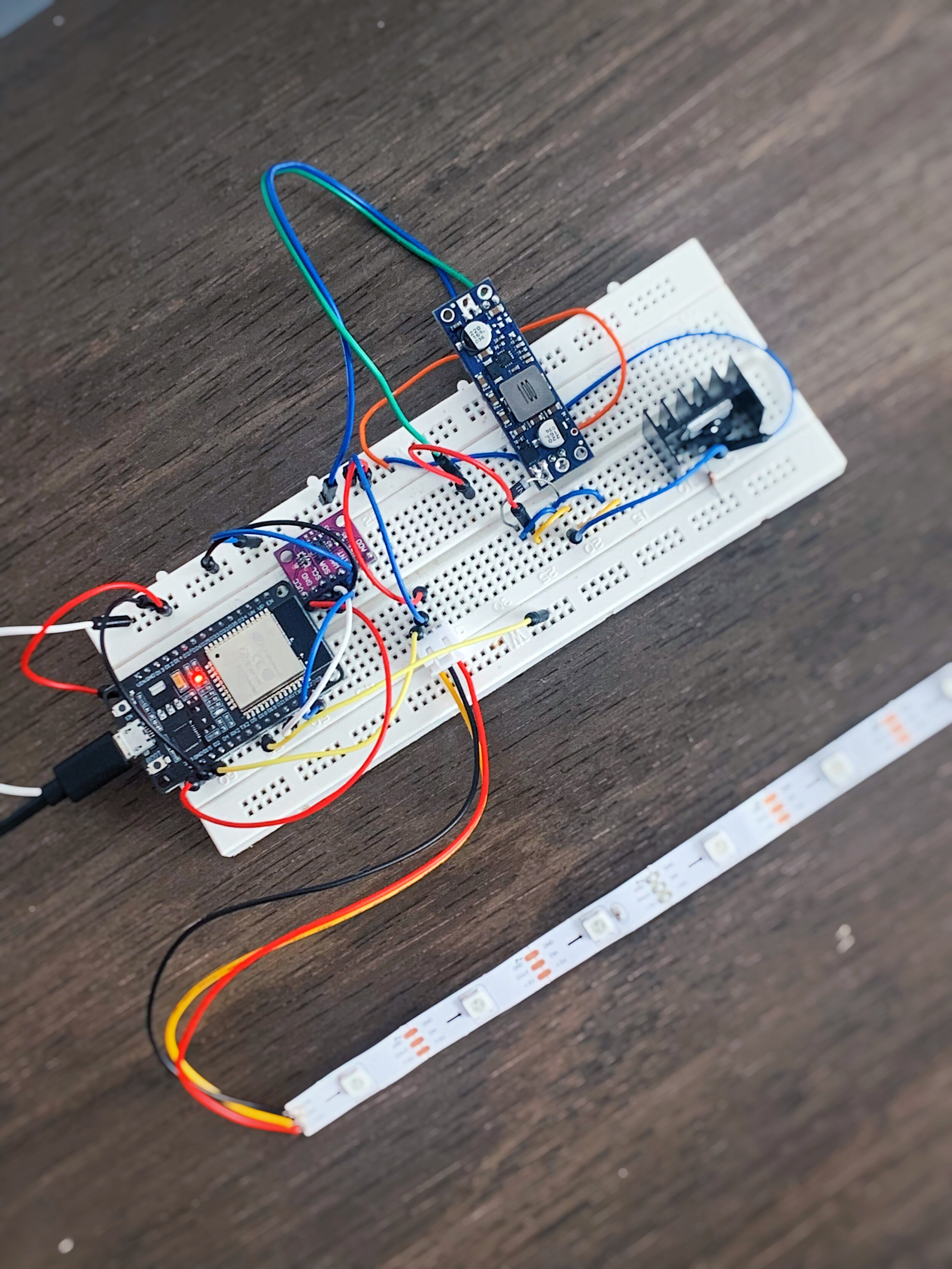

Electronics

The initial circuit was prototyped on a breadboard using an ESP32 development board and a TVOC module. The circuit was ported onto a perf board and soldered by hand to reduce size. JST connectors were used for easy connection with 12V fans and the addressable LED strip.

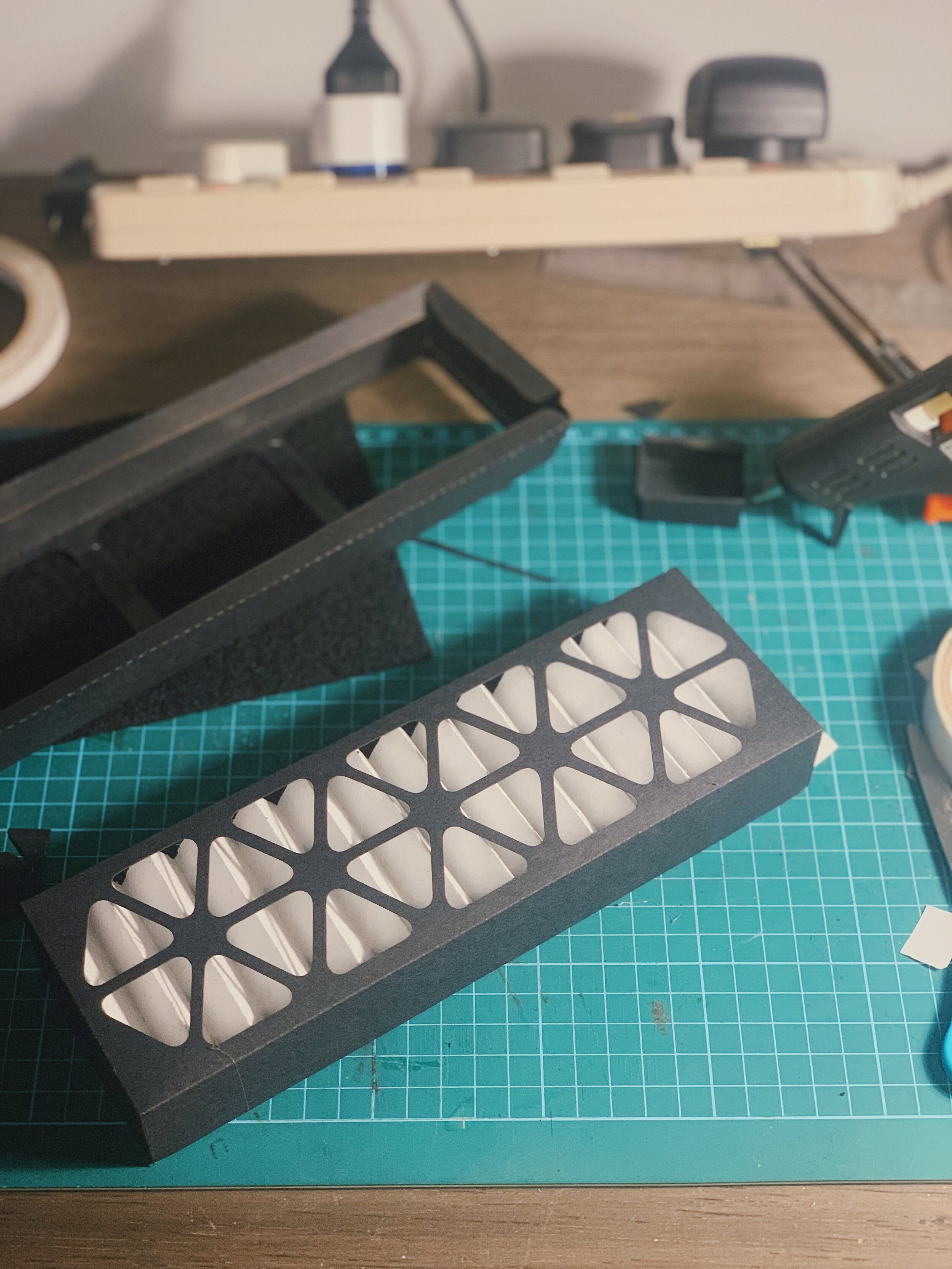

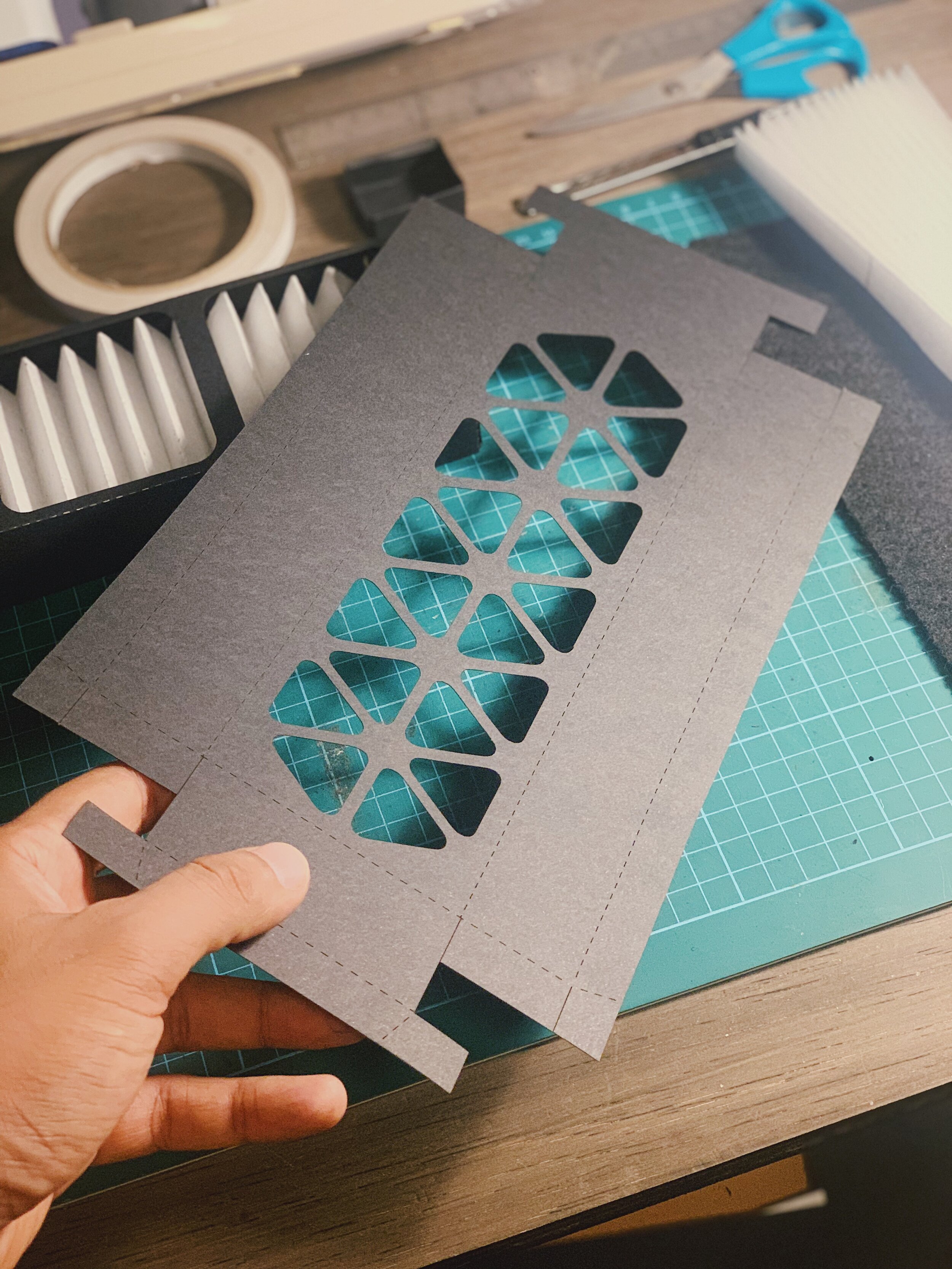

Filter Fabrication

The 240mm x 80mm was made using HEPA filter media and activated charcoal sheets. The box was constructed by laser cutting 320 gsm paper and assembling it with double sided tape and hot glue. The result is an effective and easy to replace filter box.